Tianfu textile inspection and packaging system has been successfully applied in many provinces, regions and overseas. Tianfu company combines the advanced product and insurance concept of many textile printing and dyeing enterprises, and provides detailed planning scheme in the printing and dyeing industry for many years, and further improves the management level of cloth inspection. Tianfu cloth inspection and packaging system is suitable for weaving, printing and dyeing, cloth trade, clothing, third party inspection and so on. The system can run with ERP system of textile printing and dyeing enterprises, and also can run as an independent system.

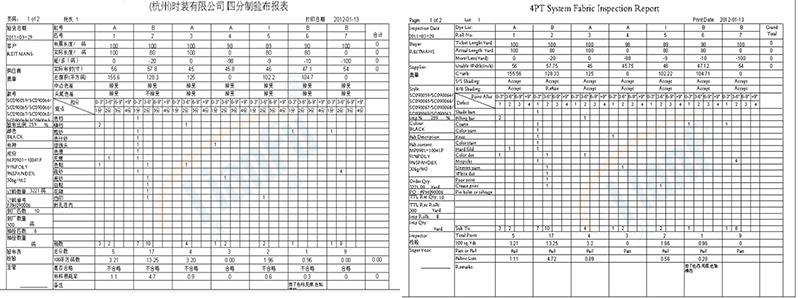

Inspection site

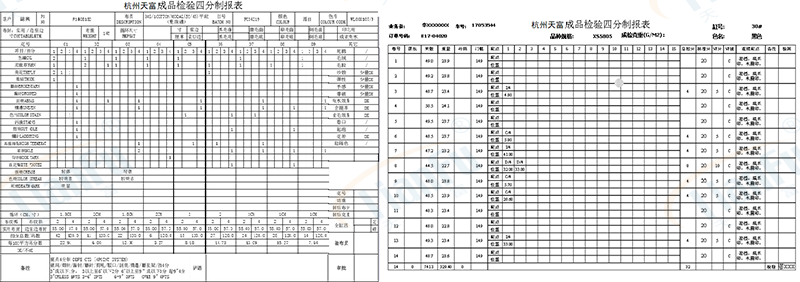

Four sub report

Barcode Label

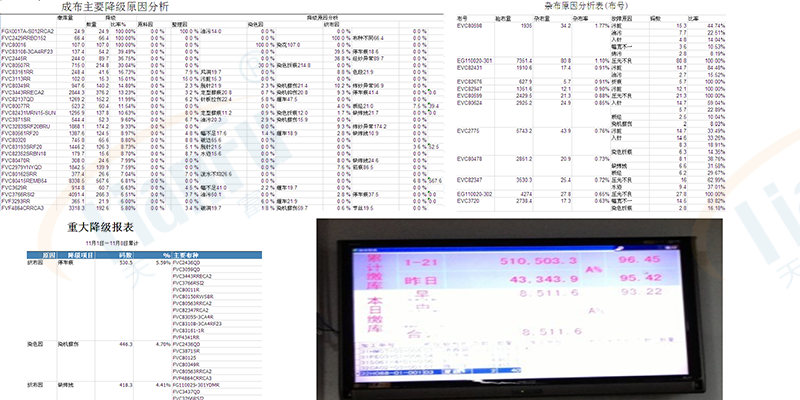

Inspection and analysis report and field Kanban